Special solution for cleanroom shoes

HEUTE Maschinenfabrik propose des solutions spéciales individuelles pour les exigences particulières. Découvrez tout ce qu'il faut savoir sur notre installation spéciale pour le nettoyage des chaussures de salles blanches dans l'entreprise autrichienne Infineon Technologies Austria AG.

The initial situation

As a manufacturer of power electronics, e.g. chips for automotive, industrial and consumer electronics, Infineon Technologies in Villach, Austria, has very high standards when it comes to hygiene and cleanliness. Even the smallest particles can render a chip unusable.

This is why the sensitive products are manufactured in clean rooms. As few particles as possible should be present in these areas. For this reason, employees at Infineon change their footwear before entering the highly sensitive areas. In special changing areas, the "normal" work shoes are exchanged for cleanroom shoes.

Cleanroom shoes have special properties such as low static charge and high slip resistance. They are also easier to clean and disinfect than other shoes.

At Infineon, employees work in three shifts, which means that cleanroom shoes are constantly in use and need to be thoroughly cleaned so that they can be used again in the cleanroom the following day. This cleaning is carried out by a service employee, who cleans the shoes individually and prepares them for reuse.

The challenge

An enquiry was therefore sent to HEUTE. The requirement was for a cleaning machine for the soles of the cleanroom shoes. It needed to be mobile, as there are three access points to cleanrooms in the company. It also had to be as self-sufficient as possible, as there are no additional connections (e.g. water or compressed air) in the changing areas. Of course, the cleaning function should still be excellent in order to remove even the smallest particles and adhesions and thus ensure the product safety of the chips produced. The machine should also clean and bind dust in the sole profiles and heel areas that cannot be removed with standard adhesive mats.

The solution

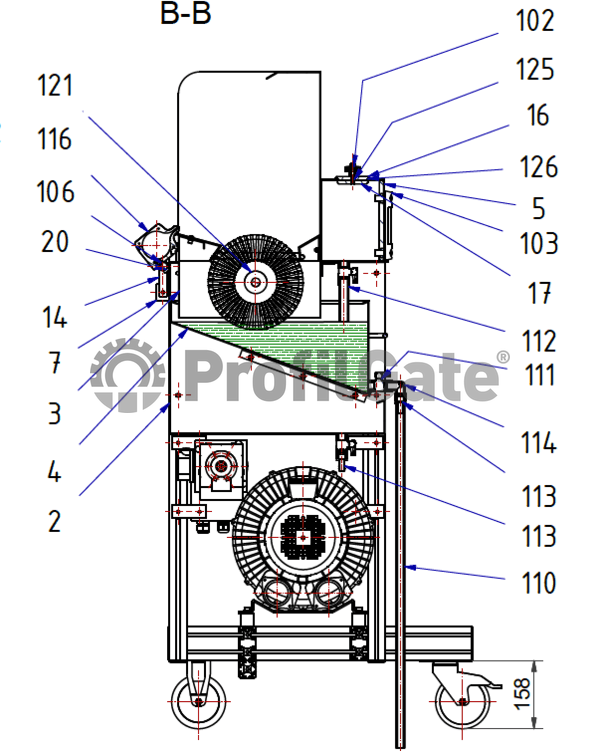

The customised solution from HEUTE Maschinenfabrik is a mobile sole washer with an integrated dryer. Despite its many functions, the machine is compact and can be moved on castors. It is therefore easy for the employee concerned to move and can easily be moved from one changing area to the next.

It only requires a power connection, as a reservoir for water with soil remover is already integrated. This container is filled at the start of the shift so that no additional liquid needs to be added at the place of use. The principle works like a bird bath. The cleaning solution collects in a basin. The size of the basin is calculated precisely so that if liquid is lost, exactly the right amount is added from the reservoir. The basin contains a brush that can be activated using a foot pedal. This means that the employee has both hands free to press the sole of the cleanroom shoe onto the rotating bristles.

|  |  |

Special system from HEUTE Maschinenfabrik for cleaning cleanroom shoe soles.

The dryer can be started using a second foot pedal. This is operated by a motor inside the machine. Compressed air is expelled from a narrow opening at the front of the machine via a hose. The employee can now pull the shoe that has just been cleaned over the opening and the compressed air ensures quick and effective drying. The blown-off liquid is fed back into the water basin via the enclosure. This is because the shoes may only be returned to the shoe racks when they are dry.

The device has been in use since summer 2018 and has already cleaned and dried many thousands of cleanroom shoes in the meantime.

Find out more here.

YOUR PERSONAL CONTACT

HEUTE Maschinenfabrik GmbH & Co. KG

Höhscheider Weg 37

42699 Solingen

Monday till Friday

09:00 bis 17:00 Uhr