THE GATE TO A CLEAN CHEMICAL/RAW MATERIALS INDUSTRY

Stops contamination such as chemical residues (salts) at the entrances and passages of your production and logistics halls.

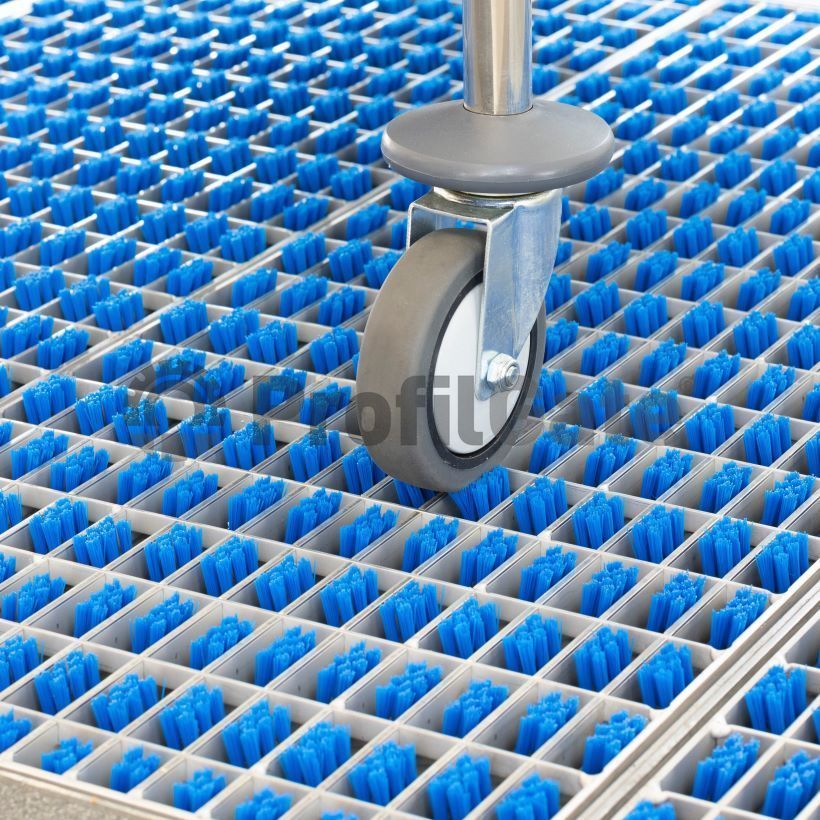

Our clean driving zones are integrated into the heavily frequented transport routes and clean the shoes and castors of vehicles every time they are driven over / walked over.

To prevent dirt from being carried further into production and logistics halls, the clean driving zones collect the dirt in easy-to-clean collection trays.

We know that the chemical and raw materials industry has to be very careful that different materials do not mix or contaminate products to avoid costly recalls. Conventional adhesive mats are often not sufficient to guarantee product safety. This can quickly lead to increased production costs because the quality of the contaminated goods has to be restored.

Separate sensitive areas with individual clean driving zones or hygiene sluices to reduce high production and cleaning costs and ensure a smooth and safe production process.

Separate sensitive areas with our process-reliable clean driving zone to reduce high production and cleaning costs and ensure a trouble-free and safe production process.

ProfilGate® is the only system whose brushes move back and forth manually as a result of the vibrations caused by driving over them.

PROFILGATE® MODELS

These clean driving zones are typically used in the chemical and raw materials industries:

in use by our customers in the chemical and raw materials industry

also rely on ProfilGate® solutions

YOUR INDUSTRY EXPERT

HEUTE Maschinenfabrik GmbH & Co. KG

Höhscheider Weg 37

42699 Solingen

Monday till Friday

09:00 bis 17:00 Uhr

FAQ - CLEAN PRODUCTION AND LOGISTICS HALLS IN THE CHEMICAL AND RAW MATERIALS INDUSTRY

How can the carry-over of chemical and raw material residues in the chemical/raw materials industry be prevented? What can be done to prevent cross-contamination in the chemical/raw materials industry and how can production costs be reduced?

Here you will find important answers to the most frequently asked questions about cleanliness in the chemical and raw materials industry.