THE GATE TO A HYGIENIC FOOD PROCESSING INDUSTRY

Stops the spread of germs and reduces cross-contamination at the entry and transition points from unclean to clean areas.

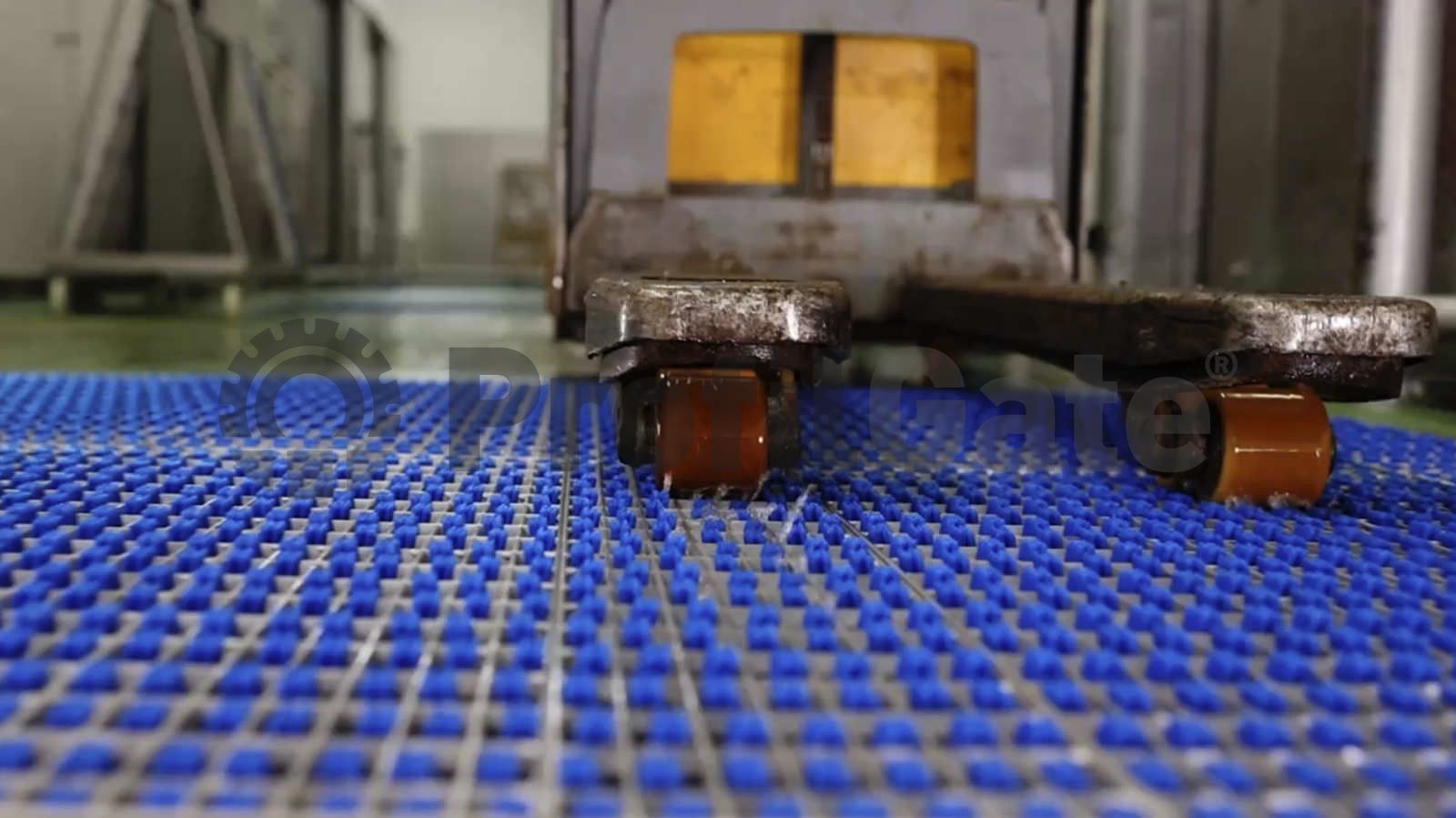

Our process-safe hygiene sluices clean both the rollers of vehicles and the soles of your employees' shoes without effort and waiting times.

Facilitates the achievement of important hygiene standards such as HACCP, ISO, IFS, GMP or BRC.

We know that food industries such as butchers, cheesemakers and dairies have to fulfil particularly high hygiene standards (HCCP, ISO, IFS, BRC or GMP). Devices such as sole washers are used to create process-safe transitions. However, the lack of cleaning of tyres and rollers of transport systems is forgotten. This can become a costly hygiene gap if germs, bacteria and viruses get into sensitive areas.

Add a reliable and effective hygiene module to your production facility, reduce the risk of cross-contamination and make it easier to pass certification inspections in your industry.

ProfilGate® is the only system whose brushes move back and forth manually as a result of the vibrations caused by driving over them.

PROFILGATE® MODELS

These clean driving zones are typically used in the food processing industry:

Model i aqua spray

in use by our customers in the food processing industry

also rely on ProfilGate® solutions

YOUR INDUSTRY EXPERT

HEUTE Maschinenfabrik GmbH & Co. KG

Höhscheider Weg 37

42699 Solingen

Monday till Friday

09:00 bis 17:00 Uhr

FAQ - CLEAN PRODUCTION AND LOGISTICS HALLS IN THE FOOD INDUSTRY

Are there alternatives to electric sole washers? Which hygiene/disinfection sluices are used in the food industry and what hygiene standards are required?

Here you will find important answers to the most frequently asked questions about hygiene in the food industry, such as butcher's shops, cheese dairies and dairies.