THE PATENT

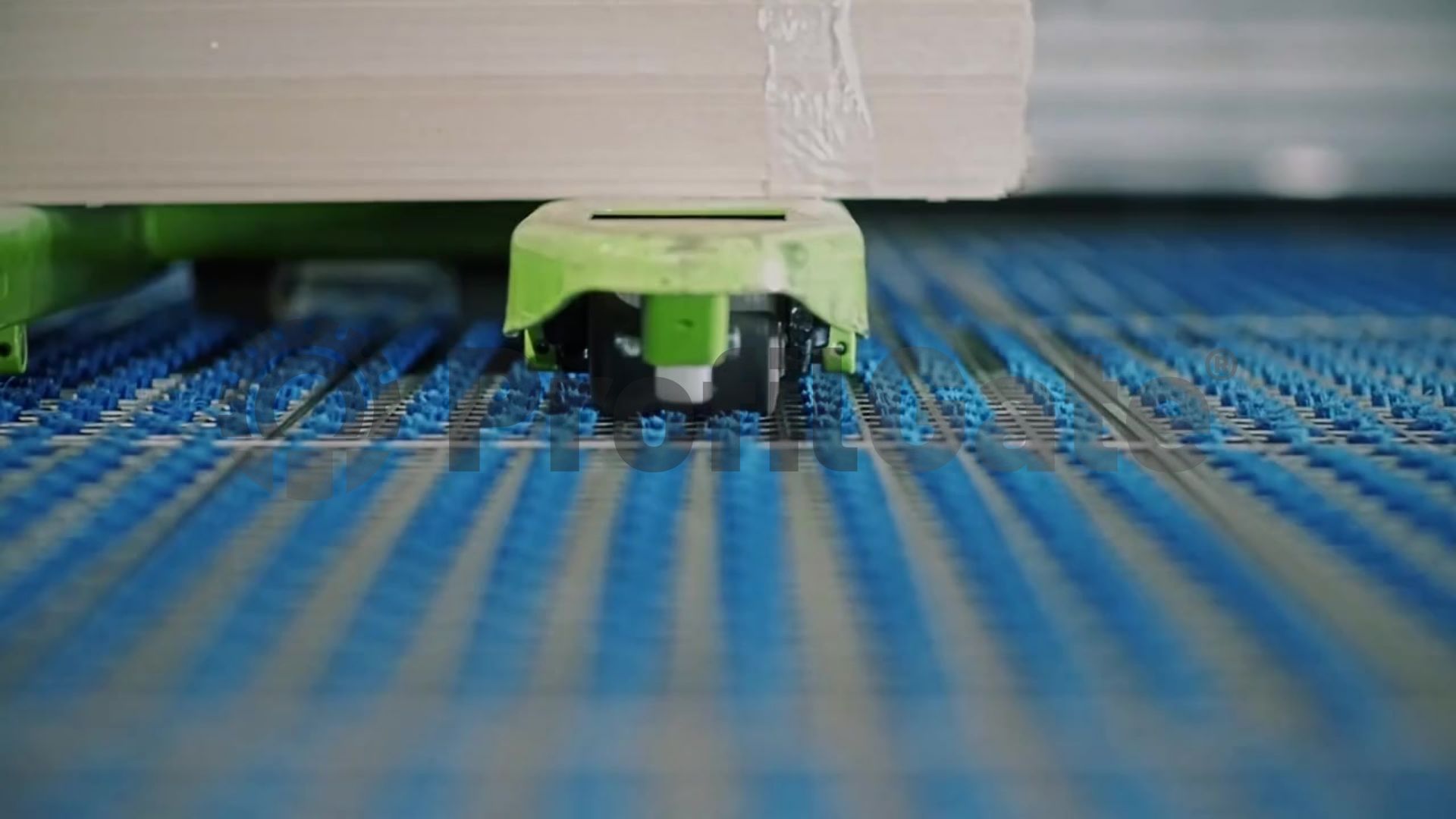

With three tyre rotations, up to 80 % * of all dirt is removed and collected in a collection tray under the brush strips. Tested by the Fraunhofer Institute for Manufacturing Engineering and Automation IPA

We explain how this works here.

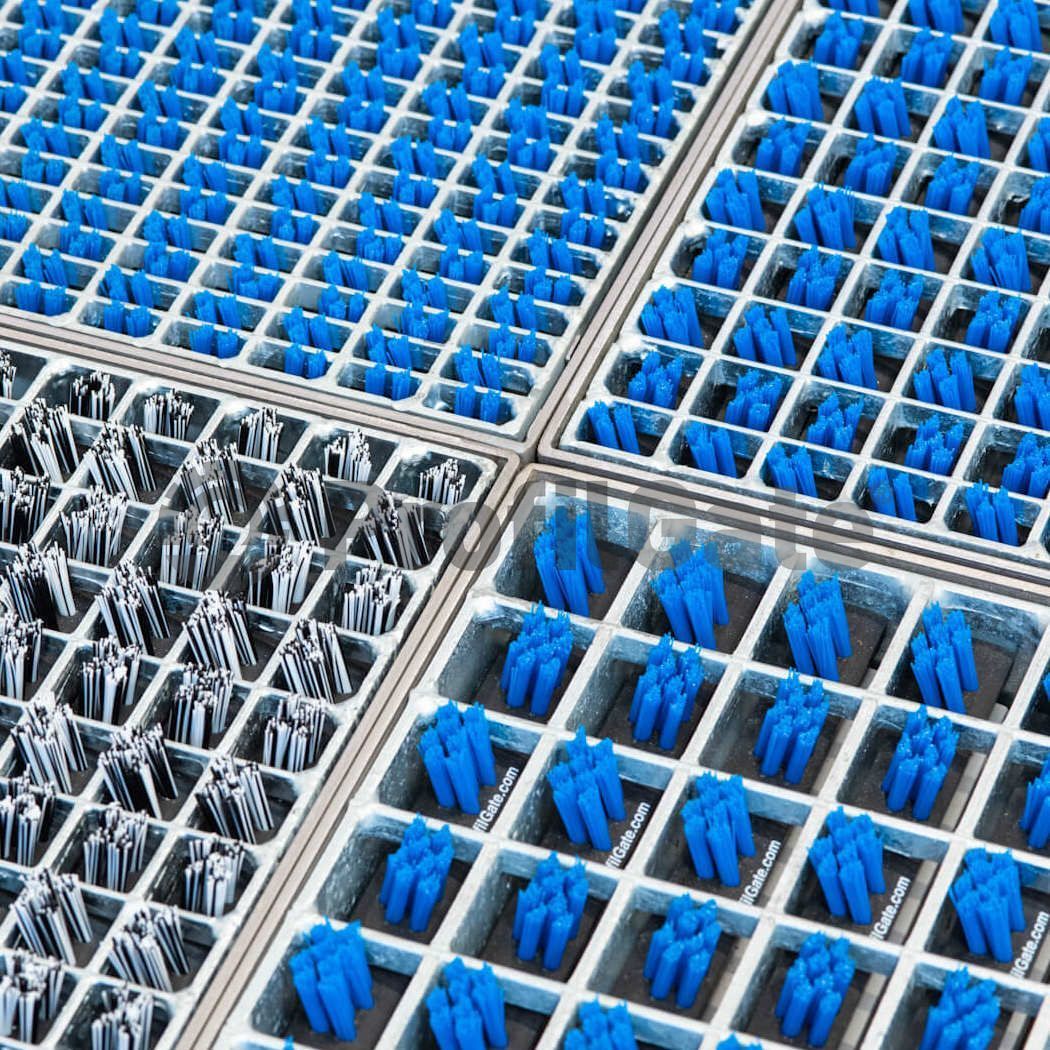

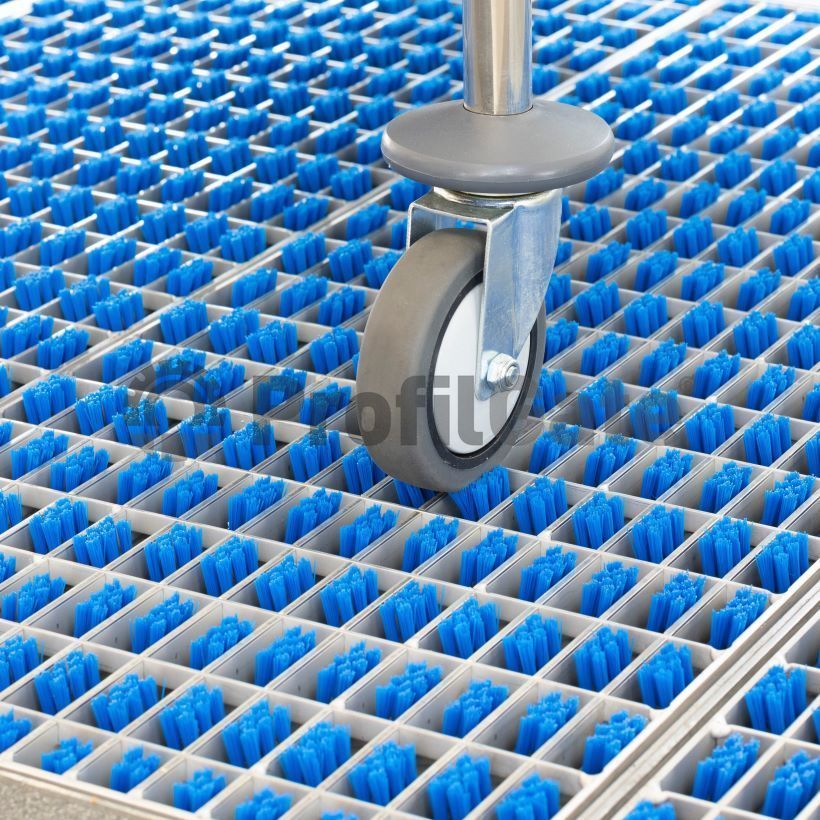

ProfilGate® clean driving zones consist of three parts:

- stainless steel dirt traps embedded in the floor

- stable grates

- patented brush strips

We emphasise the highest quality for all components and materials and manufacture exclusively in Germany.

When walking or driving over the Clean Off mats, a manual left-right movement is created that effectively removes adhering dirt particles from the walking surfaces. The abraded dirt then collects in the dirt collection trays underneath the gratings.

The various details of the brush strips are the centrepiece of our patent. Here you can see which details are important to ensure that the brushes as a whole are more than just a doormat.

An impressive number of different designs are already based on the ProfilGate patent and are cleaning all over the world. Take a look at the range.

You can also find the matching accessories with just one click:

Model i aqua spray

YOUR CONTACT PARTNER

HEUTE Maschinenfabrik GmbH & Co. KG

Höhscheider Weg 37

42699 Solingen

Monday till Friday

09:00 bis 17:00 Uhr